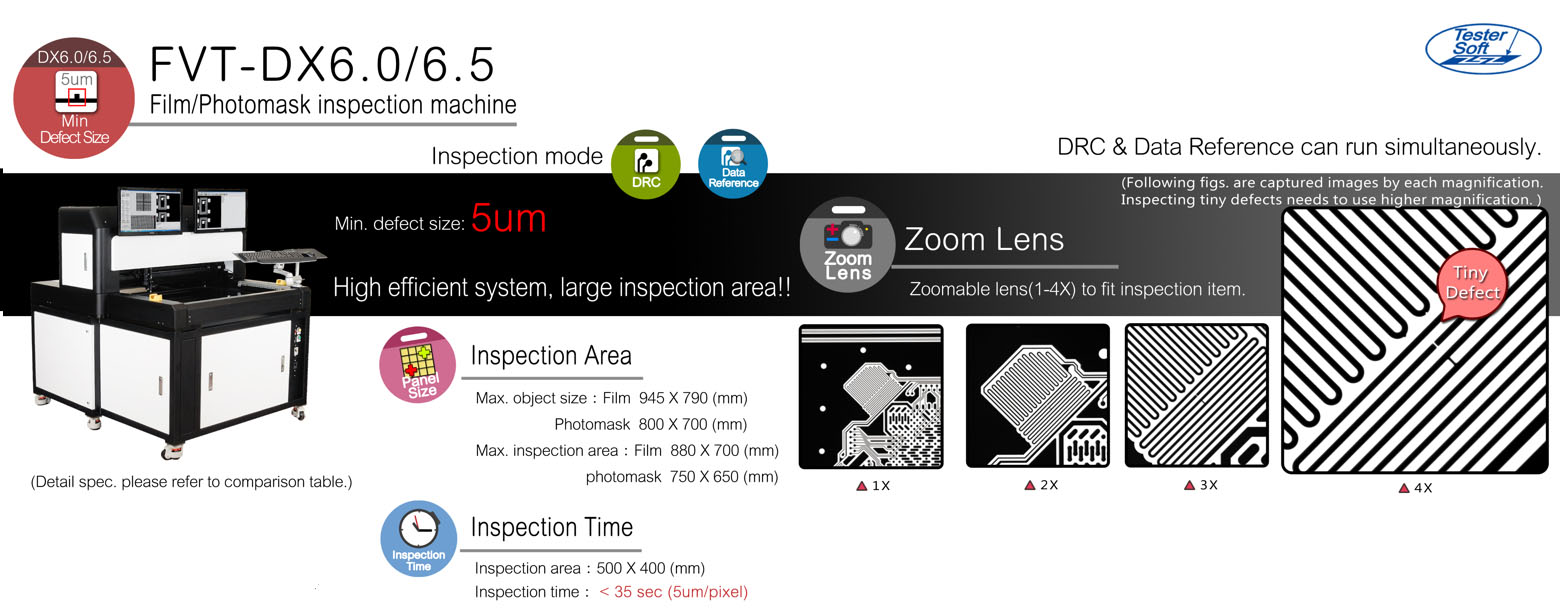

Inspect defects on the film/ photomask by optical lens capturing system. The inspection system can reduce damages and promote product quality. With adjustable magnification lens, you can adjust the magnification for different specifications of the sample, the application is more flexibility.