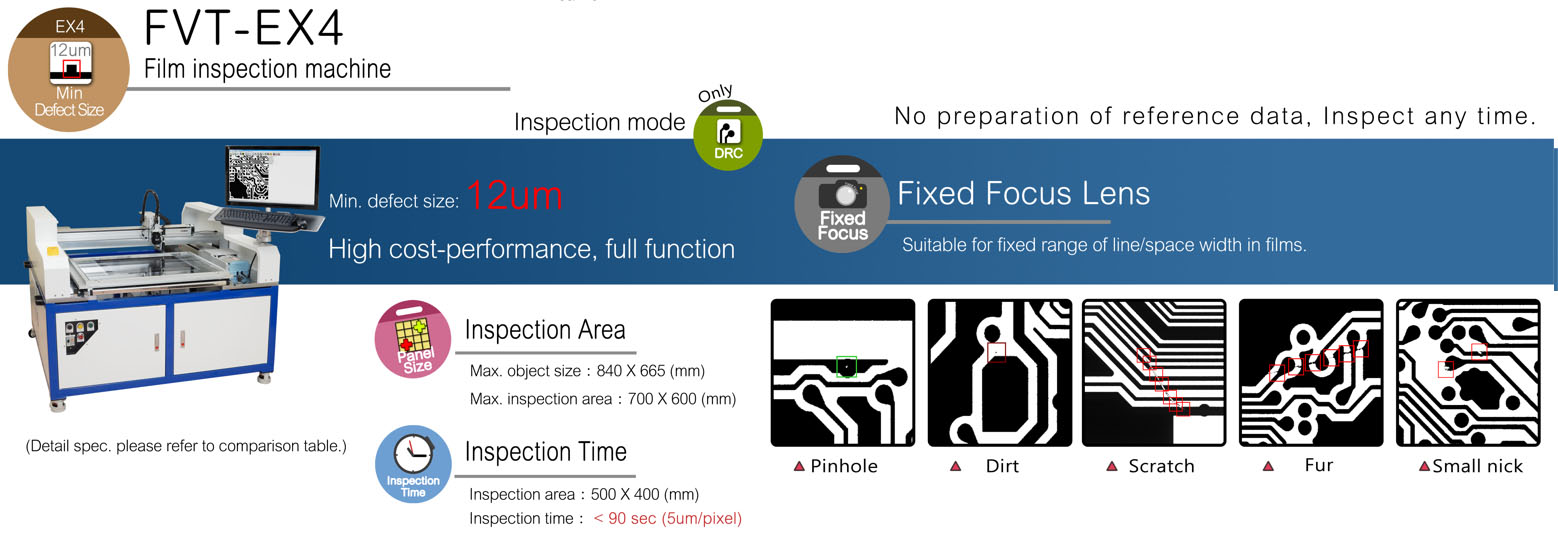

High cost effectiveness, full function.

No preparation of reference data, inspect anytime.

EX4 is applied for line/space width down to 40um

Minimum defect size: 12um

High cost effectiveness, full function.

No preparation of reference data, inspect anytime.

EX4 is applied for line/space width down to 40um

Minimum defect size: 12um